Kent Falls Brewing Co |

Enjoy a flight or individual petite pour in our tasting room, and choose from our latest releases in cans and bottles to-go.

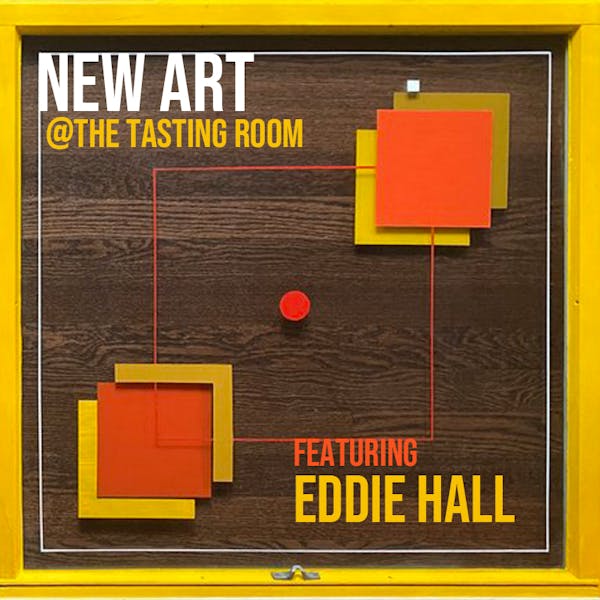

Beer Releases & Upcoming Events

view more: beer releases | events | blog

Stay Informed

Be the first to hear about the latest beer releases, events, and news.